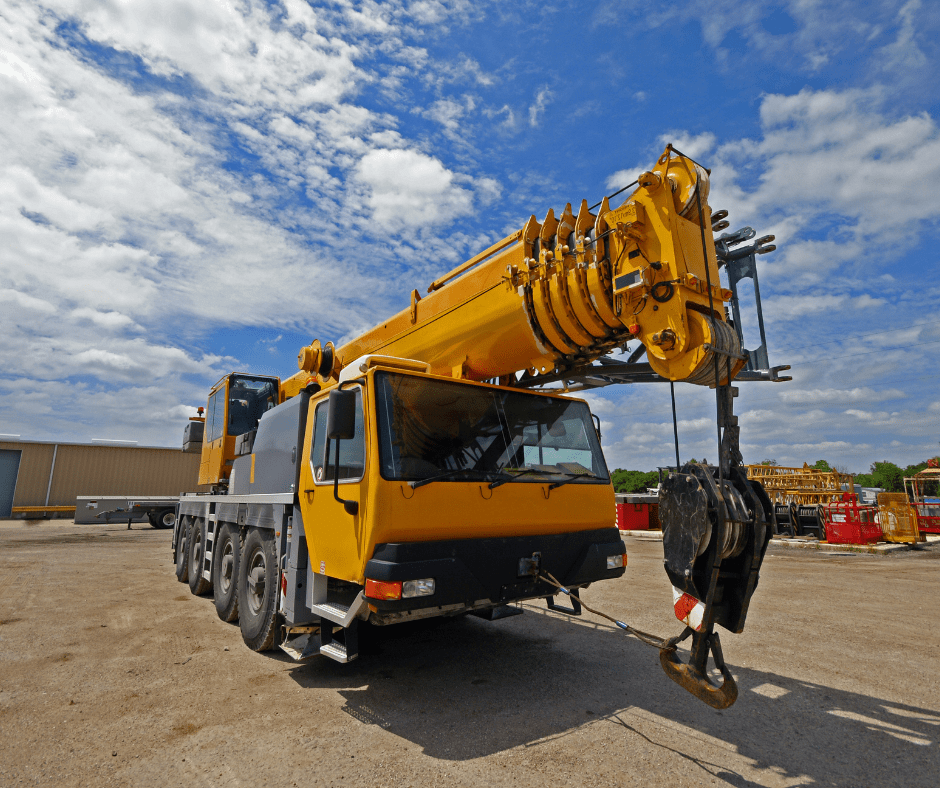

TLILIC0023 – LICENCE TO OPERATE A MOBILE SLEWING CRANE (up to 60 tonnes)

This unit specifies the skills and knowledge required to safely operate a slewing mobile crane with a Maximum Rated Capacity (MRC) up to 60 tonnes in accordance with all relevant legislative responsibilities. Competence in this unit, does not in itself result in a High-Risk Work Licence (HRWL) to operate this plant.

Slewing mobile crane means a mobile crane incorporating a boom or jib that can be slewed, but does not include:

- A front-end loader, or

- a backhoe, or

- an excavator, or

- other earth moving equipment, when configured for crane operation.

A person performing this work is required to hold a slewing mobile crane with an MRC up to 60 tonnes HRWL.

This unit requires a person operating a slewing mobile crane with an MRC up to 60 tonnes to:

- plan for the work/task

- prepare for the work/task

- perform work/task

- pack up

|

Plan work/task |

1.1 |

Task requirements are identified from work orders or equivalent, a lift plan is confirmed with associated personnel and a site inspection is conducted in accordance with workplace procedures |

|

|

1.2 |

Work area operating surface is confirmed to determine ground suitability for operational use of mobile crane in accordance with lift plan, safe work and workplace procedures |

||

|

|

1.3 |

Mobile crane Rated Capacity (RC) and the lifting gear Working Load Limit (WLL) are established and suitable for the load/s and work/task requirements in accordance with manufacturer requirements and workplace procedures |

|

|

1.4 |

Appropriate paths for operating the mobile crane and moving and placing load/s in work area are assessed and determined in accordance with workplace procedures |

||

|

1.5 |

Relevant hazard identification and risk elimination/control measures are applied and advised to associated personnel in accordance with workplace procedures |

||

|

1.6 |

Traffic management plan implementation is confirmed in accordance with workplace procedures |

||

|

1.7 |

Appropriate communication procedures are identified with associated personnel in accordance with workplace procedures |

||

|

1.8 |

All crane and lifting operations are confirmed to ensure relevant work area requirements are correct in accordance with a lift plan and workplace procedures |

||

|

1.9 |

Information required to ensure that lifting equipment and gear inspection, use, maintenance and storage complies with manufacturer requirements is obtained and interpreted |

||

| 2 |

Prepare for work/task |

2.1 |

Consultation with workplace personnel is established and maintained to ensure all crane and lifting operations are clear and consistent with site requirements in accordance with a lift plan and workplace procedures |

|

2.2 |

Risk control measures for hazards identified are checked for implementation in accordance with the lift plan and safe work procedures |

||

|

2.3 |

Mobile crane is accessed safely in accordance with manufacturer requirements and safe work procedures |

||

|

2.4 |

Pre-start mobile crane checks are carried out and any damage and defects are reported, recorded and appropriate action is taken in accordance with manufacturer requirements and safe work procedures |

||

|

2.5 |

Mobile crane is set up correctly with any lifting gear and stabilised as per the lift plan in accordance with relevant manufacturer requirements, including load chart/s and safe work procedures |

||

|

2.6 |

Counterweight/s are set up as required in accordance with the lift plan, relevant manufacturer requirements and safe work procedures |

||

|

2.7 |

Fly jib and/or luffing fly are set up as required in accordance with specific manufacturer requirements and safe work procedures |

||

|

2.8 |

Operational checks are carried out and any damage and defects are reported, recorded and appropriate action is taken in accordance with manufacturer requirements and safe work procedures |

||

|

|

2.9 |

Crane logbook is checked to confirm current compliance, is correct for the crane type, is completed and signed and required rectifications have been signed off in accordance with manufacturer requirements and safe work procedures |

|

|

2.10 |

Weather and work environment conditions are assessed to determine any impact on mobile crane operations in accordance with manufacturer requirements and safe work procedures |

||

|

2.11 |

Weight of the load is confirmed |

||

|

2.12 |

Derated Working Load Limit (WLL) of lifting equipment resulting from selected slinging techniques is calculated and confirmed as suitable to meet the requirements of the lift plan |

||

|

2.13 |

Suitable lifting points and slinging techniques are identified |

||

|

2.14 |

Lifting equipment and gear are confirmed as ready for safe use |

||

|

2.15 |

Load destination stability is confirmed ensuring it is able to bear the load and is prepared for safe access and landing |

||

| 3 |

Perform work/task |

3.1 |

Lifts are determined to be within the RC of the mobile crane in accordance with the load chart/s and lift plan |

|

3.2 |

Boom/jib and hook block are safely positioned over the load following directions from associated personnel in accordance with the lift plan and safe work procedures |

||

|

3.3 |

Main and/or auxiliary hook, including any lifting gear where required, are connected to the load and used safely in accordance with the lift plan, safe work procedures and manufacturer requirements |

||

|

3.4 |

Test lift is carried out in accordance with dogging and safe work procedures |

||

|

3.5 |

Loads are transferred using relevant crane movements and tag lines, as required, in accordance with lift plan and safe work procedures |

||

|

3.6 |

Load and crane movement is monitored constantly and crane is operated safely in accordance with lift plan and safe work procedures |

||

|

3.7 |

All required communication signals are correctly interpreted and followed whilst crane is operated in accordance with the lift plan and safe work procedures |

||

|

3.8 |

Load is lowered and landed safely in accordance with lift plan and safe work procedures |

||

|

|

3.9 |

Lifting gear is positioned for safe disconnection from the load and crane is positioned for next task in accordance with lift plan and safe work procedures |

|

|

3.10 |

Lifting equipment and gear are inspected for defects, and defective items are isolated, labelled and reported |

||

| 4 |

Pack up |

4.1 |

Crane boom/jib, lifting gear and associated equipment are stowed and secured as required in accordance with manufacturer requirements and safe work procedures |

|

4.2 |

Crane fly jib and/or luffing fly and counterweight/s are removed to storage position and secured as required in accordance with manufacturer requirements and safe work procedures |

||

|

4.3 |

Relevant motion locks and brakes are applied as required in accordance with manufacturer requirements and safe work procedures |

||

|

4.4 |

Outriggers, plates and/or packing are stowed and secured in accordance with manufacturer requirements and safe work procedures |

||

|

4.5 |

Crane is shut down and secured to prevent unauthorised access/use in accordance with safe work procedures |

||

|

4.6 |

Shutdown crane checks are carried out in accordance with safe work procedures and manufacturer requirements |

- 5 days including SafeWork NSW assessment

- $2000.00

-

Applicants deemed not yet competent will be provided the opportunity to undergo further training.

-

Applicants cannot be reassessed for a minimum of 48 hours from the date of the original assessment.Note: there may be an extra cost for re-assessment

This application is to be lodged at Australia Post which incurs and additional cost payable to Australia Post.

You will need to go to a participating Australia Post in person to apply. You need to do this within 60 days of receiving your Notice of Satisfactory Assessment from your SafeWork NSW assessor.

You will need to take:

- your Notice of Satisfactory Assessment form

- a completed Application for a National Licence to Perform High Risk Work – New Application form (N5 form provided by your SafeWork NSW assessor). Do not sign this form, you need to sign it at Australia Post

- passport-quality photograph

- proof of identity. See evidence of identity information sheet (PDF, 109.92 KB)

- any current high risk work licences

- payment method (view the cost in the fee schedule).

• Students who give notice to cancel their enrolment more than 10 days prior to the commencement of a program will be entitled to a full refund of fees paid.

• Students who give notice to cancel their enrolment less than 10 days prior to the commencement of a program will be entitled to a 75% refund of fees paid. The amount retained (25%) by All Onsite Training and Assessment Services is required to cover the costs of administration and resources which will have already been committed based on the students initial intention to undertake the training.

• Students who cancel their enrolment after a training program has commenced will not be entitled to a refund of fees.

If All Onsite Training and Assessment Services cancels the training course, and is not rescheduling then a full refund will be returned to the payer.

- All students must pass a language, literacy & numeracy assessment (LLN)

- Minimum 18 years of age (Workplace Health and Safety requirement)

- PPE is required including safety boots and a hi-vis shirt

- Identification must be the originals and not laminated,

- 100 points Safework NSW EOI – SW08446-0718-423971.pdf

- Unique Student Identifier Number – http://www.usi.gov.au/create-your-USI/Pages/default.aspx – if you need help with this our trainer will help you on the day.

All equipment

All courseware and handouts

Please refer to the AOTA Student Handbook on the Student Resources Page, as well as:

AOTA can train all of the below, but we require access to the crane. The courses covered are:

- TLILIC0011 Licence to operate a reach stacker (greater than 3 tonnes capacity) https://training.gov.au/Training/Details/TLILIC0011

- TLILIC0016 Licence to operate a bridge and gantry crane https://training.gov.au/Training/Details/TLILIC0016

- TLILIC0020 Licence to operate a slewing mobile crane (over 100 Tonnes) https://training.gov.au/Training/Details/TLILIC0020

- TLILIC0021 Licence to operate a slewing mobile crane (up to 100 Tonnes) https://training.gov.au/Training/Details/TLILIC0021

- TLILIC0022 Licence to operate a slewing mobile crane (up to 20 tonnes) https://training.gov.au/Training/Details/TLILIC0022

- TLILIC0024 Licence to operate a vehicle loading crane (capacity 10 metre tonnes and above) https://training.gov.au/Training/Details/TLILIC0024

- TLILIC0040 Licence to operate a non-slewing mobile crane (greater than 3 tonnes capacity) https://training.gov.au/Training/Details/TLILIC0040

We can also provide training and assessment for companies.